Certified materials and treatments

We collaborate with a select network of strategic suppliers to ensure the highest quality and traceability throughout the entire production chain.

We manage all heat and surface treatment requests comprehensively and promptly, relying on qualified partners capable of meeting every technical requirement, in full compliance with regulations and agreed upon deadlines.

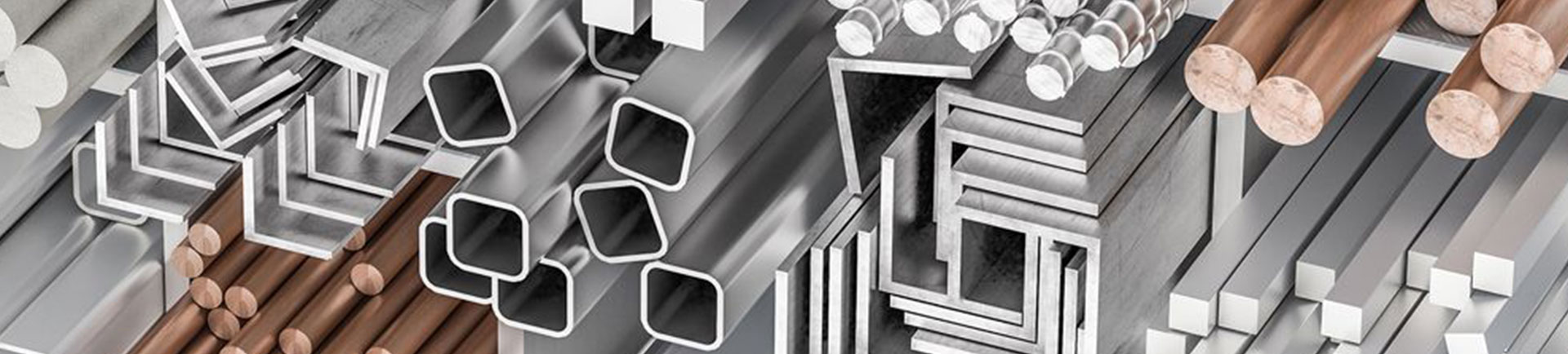

Regarding materials, we rely on reliable suppliers capable of guaranteeing a wide range of metals and specialty alloys, with the option of providing certifications of origin and compliance upon customer request.

This approach allows us to offer complete, certified, and traceable mechanical processing, ensuring a final result worthy of even the most demanding sectors.

Ferrous materials

Oxidable

- Carbon for Tempering C45 – 42CrMo4 – 39NiCrMo3 – ASTM – A105

- For Casehardening16MnCr5 – 20MnCr5 – 18NiCrMo

- For Surface Hardening C43 – 40NiCrMo3

- Automatics 11SMnPb30 – 11SMn30 – 11SMnPb37 – 36SMnPb14

- Chrome Bars Chrome Tubes (Dimensions: mostly round. In some cases, flat and square)

- Mechanical and Hydraulic Pipes

- Square and Triangular Hollow

- Internal h8 Seamless Drawn Tubes

- Seamless Drawn Tubes

- Welded Drawn Tubes

- Non-Structural Alloys S235JR, S235J2, S275JR, S275J0, S355J0, S355J2, E295, E335

- Cast Iron

Stainless steel

- EN 10088-2 EN 10028-7 AISI 304/304L, AISI 321, AISI 316L, 316TI

- EN 10088-3 DIN 1017 AISI 304/304L, AISI 316/316L

- EN 10088-3 AISI 303, 304, 304L, 316, 316L, 316Ti, 321, 310S

- EN 10088-3 AISI 304/304L, AISI 303, AISI 316/316L

- EN 10088-3 DIN 1014 AISI 304/304L, AISI 316/316L

- EN 10088-3 DIN 178 AISI 304/304L, AISI 316/316L

- EN 10056-1 DIN 1028 AISI 304/304L, AISI 316/316L

- EN 1.4307

- Round pipes ASTM A312/ A213 / A269 EN10216-5 AISI304/304L, AISI 316/316L

- Austenitic stainless steel seamless tubes

- Stainless steel perforated bars

- Laser and Waterjet cuts can be made in AISI303, AISI304, AISI316

- And other special materials also available AISI440, AISI 420 1.4028, AISI 630 1.4542, altri materiali speciali

- Steel duplex e superduplex

Non ferrous materials

Titanium

Aluminium

- Series 1000

- Series 2000

- Series 5000

- Series 6000

- Series 7000

Brass

- CW612N-CuZn39Pb2 – OT59

- CW505L-CuZn30 – OT70

- CW614N-CuZn39Pb3 – OT58

- CW506L-CuZn33 – OT67

- CW617N-CuZn40Pb2 – OT58

- CW508L-CuZn37 – OT63

- CW618N-CuZn40Pb2Al – OT58

- CW509L-CuZn40 – OT60

- CW620N-CuZn41PbAl – OT58

Tin bronze

- UNI EN 1982

- CC491K

- CC493K

- CuSn12-C

- CC483K

Bronze alluminium

- CW612N-CuZn39Pb2 – OT59

- CW505L-CuZn30 – OT70

- CW614N-CuZn39Pb3 – OT58

- CW506L-CuZn33 – OT67

- CW617N-CuZn40Pb2 – OT58

- CW508L-CuZn37 – OT63

- CW618N-CuZn40Pb2Al – OT58

- CW509L-CuZn40 – OT60

- CW620N-CuZn41PbAl – OT58

Plastic materials

- PA – POLIAMMIDE AKULON®

- PA 6G – POLIAMMIDE OMNIAMID

- POM – POLIOSSIMETILENE OMNIACETAL

- PET – POLIETILENTEREFTALATO ARNITE

- PE – POLIETILENE PE HMW / UHMW

- PP – POLIPROPILENE

- PTFE – POLITETRAFLUOROETILENE

- PVDF – POLIVINILDENFLUORURO FORAFLON

- PC – POLICARBONATO

- PMMA – POLIMETILMETACRILATO

- PEEK – POLIETERETERCHETONE

- PVC – POLIVINILCLORURO

- POLIURETANO

- SINTEK

- VULKOLLAN

- KEVLAR

- FIBER

- CARBON

- POLYCARBONATE

Special mechanical processes

BROACHING

TOOTHING

SLOTTING

EDM

- Plunge EDM

- Wire EDM

- EDM Puncturing

- EDM Grinding

DEEP PUNCTURING

LAPPING

GRINDING

- Cylindrical

- Centreless

- Flat

LASER MARKING

PUNCHING

BENDING

WELDING

- Laser Welding

- Tig Welding

- Mig/Mag Welding

Heat Treatments

QUENCHING AND TEMPERING

STRESS RELIEVING

AGEING

STABILISATION

CARBURIZING (CASE HARDENING)

CARBONITRIDING

NITRIDING

STANDARDISATION

ANNEALING

(complete, isotherm, of machinability, etc)

TEMPERING

HARDENING

- Inductive hardening

- Laser hardening

- Vacuum hardening

Superficial Treatments

TENIFER®

NICHEL CROMO

NIKEL PLATING

ELETROLITYC NIKEL COATING

- Chemical Nickel Coating

- Nickel Plating

CHROME COATING

PASSIVATION

- Chromic Passivation

- Steel and Titanium Passivation

ELECTROPOLISHING

BRIGHTENING

POLISHING

SHOT PEENING

SATIN FINISHING

SAND BLASTING

ANODIC OXIDATION (ANODIZING)

- Natural / protective

- Hard Anodic

- Semi-Hard

- Hard to Sample

- Hard to Casting

- “Super coat” Treatment

BURNISHING

TUMBLING

TEFLON COATING

MIRROR POLISHING

COATING

SUPER LATEX COATING

COPPER PLATING

CERAMIC PLATING

GILDING

TUNGSTEN CARBIDE

CATAPHORESIS

- Black Cataphoresis

PAINTING

- Water based

- Vulcanization

- Powder based

PICKLING

DEHYDROGENATION

PHOSPHATING

- Manganese based

- Zinc based (ref. UNI EN ISO 9227)

- Black

GALVANISING

- Hot

- Cold

- Electrolytic

- Spray

METAL PLASTIFICATION

PTFE (Teflon®)

PVD (Phisical Vapor Deposition)

DLC

GEOMET®

- GEOMET® 500 Ref. ISO10683 – EN 13858 – ASTM F1136/F1136 M

- GEOMET® 321 Ref. ISO10683 – EN 13858 – ASTM F1136/F1136 M